EVIRT Italia smart rolling machines

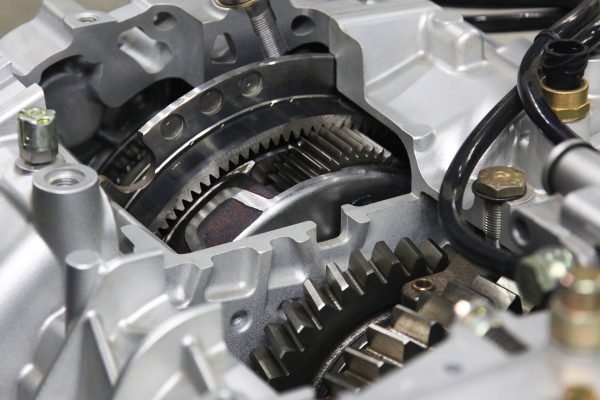

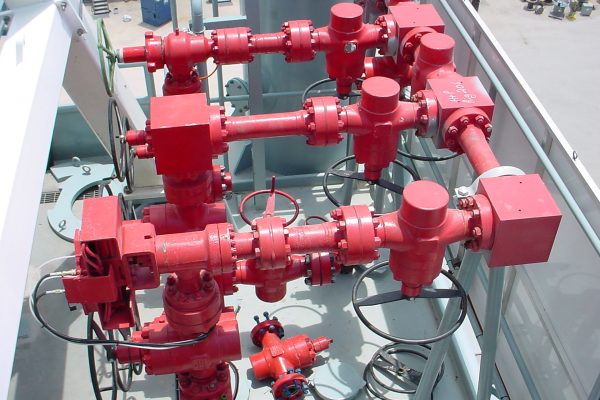

Based on 50 years of experience and designed following the last engineering innovations, EVIRT Italia rolling machines are equipped with the most recent available technological features to assure a qualitative rolling process on nearly every rotation - symmetric profile.