Spline Rolling – Evirt Italia

EVIRT ITALIA newly developed Smart Rolling Machines series

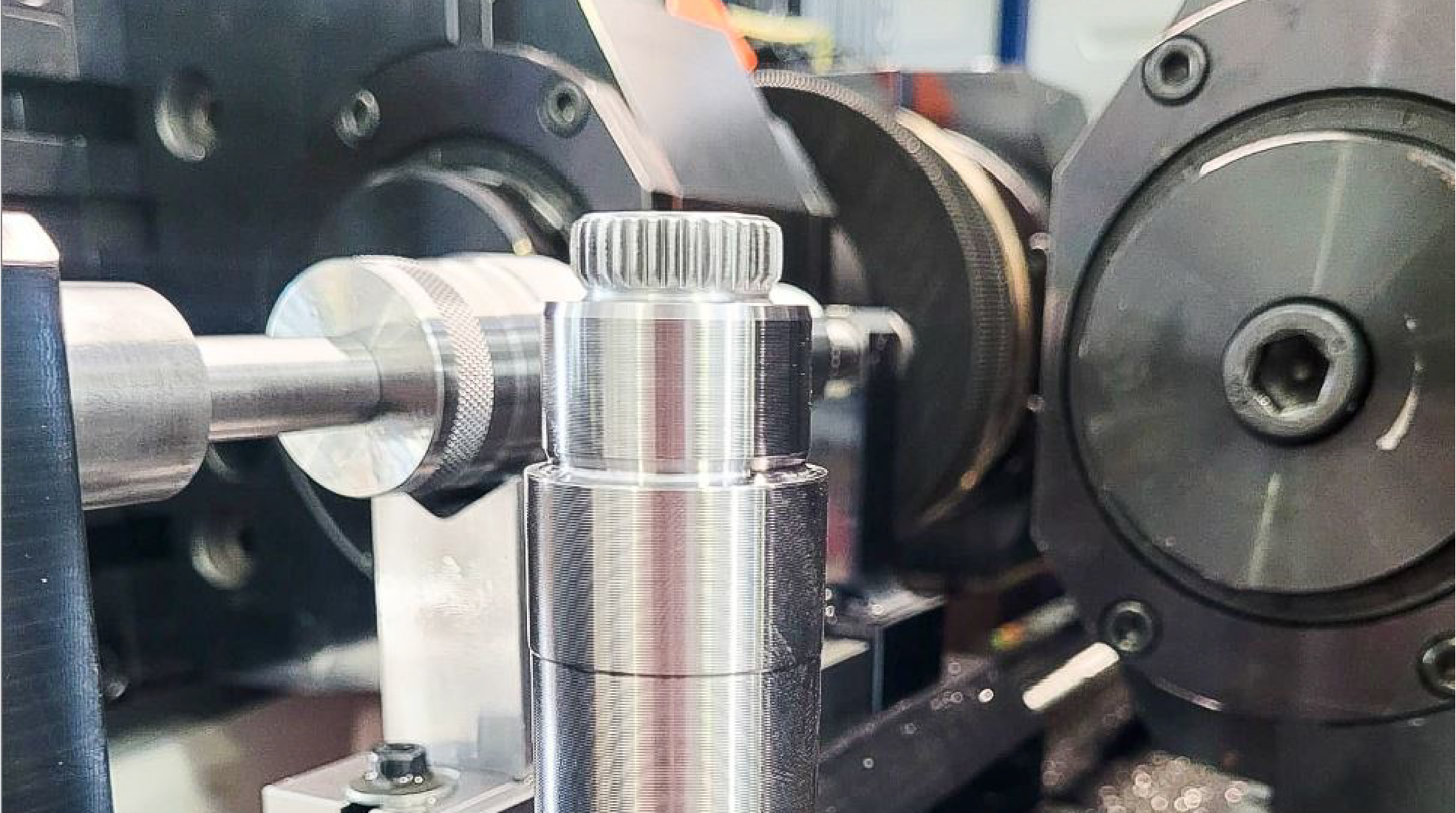

designed for Spline Rolling Processes - SplineTech series

The ever-increasing demand to use alternative energies to fuels and the development of products compatible with them has generated an enormous need to produce elements capable of transmitting rotary motions through gears or similar profiles.

Splines and serrations are typically used in torque transmitting applications requiring a precision fit to a mating part as opposed to knurls which generally do not require a precision mating fit. Half shafts, drive shafts, electric vehicle motor shafts, and power take-off shafts are common types of splined and serrated components.

During last 10 years EVIRT ITALIA invested a lot of energies and financial investment in developing reliable and precise spline rolling processes through the use of cylindrical rotating Rolling Machine. Based on very long experience in the field of rolling developed over decades of innovation in cold deformation processes using cylindrical die rolling; the new series of Smart rolling machines required an in-depth study and subsequent validation of the operating methods, accessories necessary for control, support and positioning of the work-piece which allowed the new EVIRT ITALIA SplineTech series to be today the preferred machinery for the production of superior class toothed profiles thanks to a new improved technology able to increase the processes productivity.

Evirt Italia SplineTech series for superior splines production

After a decade of researches and validating testing followed by 3 years of exclusive use and testing at some selected customers, the deeply tested EVIRT ITALIA SplineTech series is finally available for all customers.

SplineTech series advantages

- Perfect movements’ symmetry: the workpiece is always located at the center of the working area.

- Extremely short setup change times guaranteed by the commissioning functionalities available into the integrated EVIRT comfort-HMI.

- Rigid & direct coupling between spindles and brushless motors.

- AI process quality control with data export feature for report production.

- Perfect integrability with any kind of automation systems.

- Ability to allow the installation of up to 5 different tools’ sets at once.

- Through-feed spline Rolling Smart Rolling Feature;

- Precise Real-time force analysis.

The SplineTech series combines all the advantages of EVIRT ITALIA Smart Rolling Machines with a precisely developed spline rolling center engineered to move and support the workpiece in a precise and reliable way during the entire teeth forming process. The servo-controlled system, developed into EVIRT ITALIA laboratories, allows gear manufacturers to obtain greater advantages in terms of production speed, quality, flexibility and, as a logical consequence, economic profits.

The SplineTech series is produced only in CNC-controlled configuration and it present the strongly appreciated ability to simultaneously manage a wide number of tools’ sets. This feature allows all SplineTech rolling machines to manage the production of multiple grooves and/or teeth on the same shaft through a single process. The result is a stable and self-monitored production which do not require any tools replacement or process interruption.

Unlike the flat rolling process using rack tools, in which two opposing flat racks generate the required geometry, the rolling processes of the EVIRT ITALIA Smart rolling machines use two cylindrical rolling dies. The same dies, which are directly driven by brushless motors and “locked together” into a precise rotation phase, create the required profile with significantly lower and higher quality tolerances.

The teeth on splines and serrations formed on solid shafts can also be realized on the new EVIRT ITALIA SplineTech machines series using the incremental (or single-turn) rolling process.

Another frequently process feasible on the SplineTech machines when profiling hollow shafts is the forced-through feed rolling process. This process allows to obtain a rolled spline having a length greater than the thickness of the tools thanks to the pushed axial movement of the component being formed towards the inside of the rolling area. Moreover, the forced-through feed rolling process allows the instantaneous contact area to be reduced to a minimum with the consequent increase of the quality of the toothed profile.

A similar forced-through feed rolling process can also be used to profile continuous lengths of splines and serrations on both solid and hollow shafts like the hollow Transmission shafts.

SplineTech rolled applications

- Involute splines

- Precise Teeth and Knurls

- Grooves

- Worm screws

- Multiple splines

- Aligned splines

- Splines on hollow material

- Transmission shafts

- Steering shafts

- Pump shafts

- Differential shafts

- Off-Road Vehicle Components

- Crankshafts

- Heavy Tractors transmissions

- Truck braking systems

- Automotive transmission chains

- Compression shafts